Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Description of auto continous powder coating line:

This PVC Coating Line is used to provide an anti-corrosive surface treatment for steel wire roll mesh, wire mesh, mesh coil.

Technical parameters of powder dip-coating line:

(1) Application: Apply powder coatings on welded wire mesh in roll package

(2) Max. size of roll mesh: Length 30000mm * Width 2500mm

(3) Productivity: ≥3-5m/min

(4) Total installed capacity: 360KW

(5) Average power consumption: about 300KW/h

(6) Water Consumption: 2.5-3m3/h (recycled water)

(7) Factory Building: ≥ Length 30000mm * Width 10000mm * Height 5000mm

Composition of a Complete Fluidized Bed Powder Coating Line:

(1) Auto electrical pre-heating & curing furnace;

(2) Mesh de-coiler, convey type mesh re-coiler;

(3) Vibration generator, dipping PVC coated fluidized bed, spray type water cooling device, dust removing device;

(4) Power supply control equipment;

Process Flow of Wire Mesh Electrostatic Fluidized Bed Coating line:

Manual feeding - Pre-heating - Auto powder immersion - Curing - Cool the coated mesh - Manual discharging - Manual shaping correction - Quality control - Final package

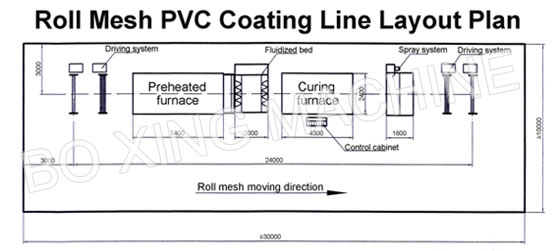

Layout Plan of Roll Mesh PVC Coating Line:

Technical requirements:

1.Plant size:≥30000mm long*10000mm wide*5000mm tall

2.Powder consumption:installed capacity 170KW,average power 150kw/h

3.Power supply:380V,220V 50hz

4. Water consumption:1.5~2.0m³/h(circulating water)

Typical PVC Coated Roll Mesh: