Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

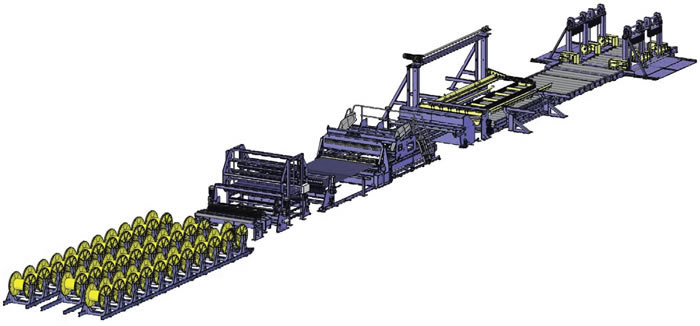

Auto reinforcing mesh welding line; reinforcing welded wire mesh machinery (5-12mm)

1 The human machine interface + PLC programmable controller mode control, high degree of automation.

2 can be welded hot-rolled ribbed , rolled ribbed , hot light circle , cold light circle and other materials, and wide adaptability.

3 according to user capacity , using once or welding , flexibility .

4 unit designed for detachable structure, easy adjustment and maintenance specifications .

5 transformers, thyristor upper and lower electrodes , such as welding system using forced water cooling , and a flow protection device , the unit can reliably work continuously .

6 welding pneumatic system pressure infinitely adjustable , quick response to reinforcement specifications transformation.

7 uniform welding pressure to ensure that all the solder joint quality .

8 longitudinal reinforcement from the disc material by straightening straightening institutions , without reprovision straightening equipment.

9 unique feeding mechanism of lift , drag lift off when the mesh electrode to ensure that the electrode life and reduce operating costs.

10. Transverse ribs blanking device uses a stepper motor automatic feeding , reduce labor intensity and improve efficiency.

11 imported digital servo motor system to ensure accurate network size .

12. Mesh size can be transformed by vertical screen input , multi-standard network to adapt to changing needs of the project 13 horizontal bars with a blanking of the magnetic bodies dumped material , blanking speed, high production efficiency.

14 electrode device has in place to ensure that the cross bars blanking reliable and accurate.

15 The unique design ensures replace steel and steel mesh specifications convenient, flexible and fast.

| Model | BX-3/6-2500 | BX-5/12-2500 | BX-5/12-3300 |

| Diameter | Ф3-Ф6mm | Ф5-Ф12mm | Ф5-Ф12mm |

| Max mesh width | 2500mm | 2500mm | 3300mm |

| Welded no. | 24 | 24 | 32 |

| Capacity of transformer | 1000KVA | 1600KVA | 16×125KVA |

| Line wire space | 50-200mm | 100-300mm | 100-300mm |

| Cross wire space | 50-200mm | 100-300mm | 100-300mm |

| Max. welding frequency | 30-65 Times/min | 30-60 Times/min | 30-60 Times/min |

| Utilization factor of transformer | 30% | 30% | 30% |

| Work pressure of pneumatic system | ≤0.8Mpa | ≤0.8Mpa | ≤0.8Mpa |

| Pressure of cooling water | 0.2Mpa-0.3Mpa | 0.2Mpa-0.3Mpa | 0.2Mpa-0.3Mpa |

| Consumption of compressed air | ≥3M3/min | ≥3M3/min | ≥3M3/min |

| Load mode of line wire | By coils | By coils | By coils |

| Load mode of cross wire | Pre-cut; straightness ≤3mm/1000mm | Pre-cut; straightness ≤3mm/1000mm | Pre-cut; straightness ≤3mm/1000mm |

Typical application of reinforcing welded wire mesh