Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

Welcome to SHIJIAZHUANG BO XING MACHINE CO., LTD.

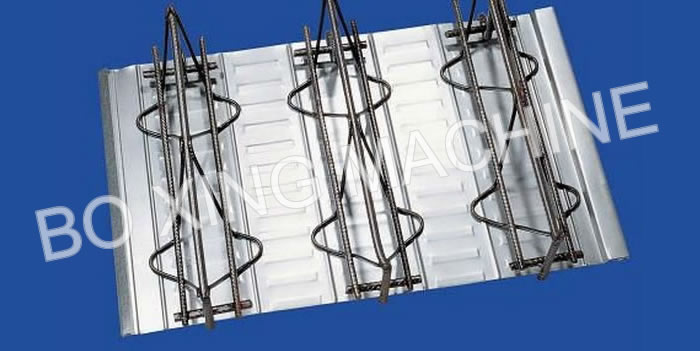

Automatic 3D Lattice girder production line, truss girder welding line

● The plant is controlled with a system which is reliable, powerful and flexible and controls all the functions of the machine and allows an easy interface with the operator. The main computer has a diagnostic system which allows an immediate check of all the signals emanating from the machine.

● All the axis parameters, machine times and speeds are adjustable from the computer.

● The programming is quick and easy so as to be as user friendly to the operator as possible.

● The welding is controlled by units which allow the operator to adjust and change the periods and the power relative to the production at hand.

● All the power apparatuses for driving the motors and all other functions are mounted in the electronic switching cabinets; all the signal lights and the various commands are found on the cabinets.

● The operator controls the plant through the electronic control stations which are positioned appropriately.

| Power supply | 380 +/-10% [V] , 50 +/-1% [Hz] | |

| Electric power of welding unit | 800 KVA (average 90KVA) | |

| Other machine power | 50 KW | |

| Source gas | Row amount | 2000 L/min at 6 Bar |

| pressure | 6 Bar | |

| Cooling water | Row amount | 150 L/min |

| Min. presuure | 3 Bar | |

| MAX water temperature | 25 C | |

| water inlet | 2 x 1" | |

| water exit | 1 x 3" | |

| Circumstance | temperature | 0 - 40 C |

| altitude | < 1000 m.a.s.l. | |

| Raw and processed material | ||

| Yield strength | MAX 600 N/mm2 | |

| Tensile strength | MAX 700 N/mm2 | |

| Elongation | > 14 % | |

| Top wire diameter | 5 - 12 mm | |

| Bottom wire diameter | 5 - 12 mm | |

| Bending wire diameter | 3.5 -6 mm | |

| Truss girder welding machine | ||

| Max welding speed | 12m/mi | |

The finished products;